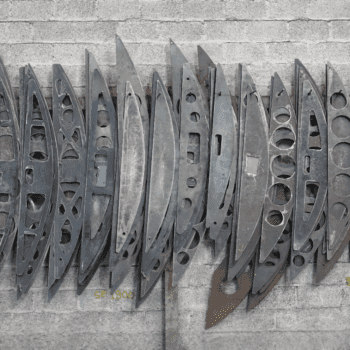

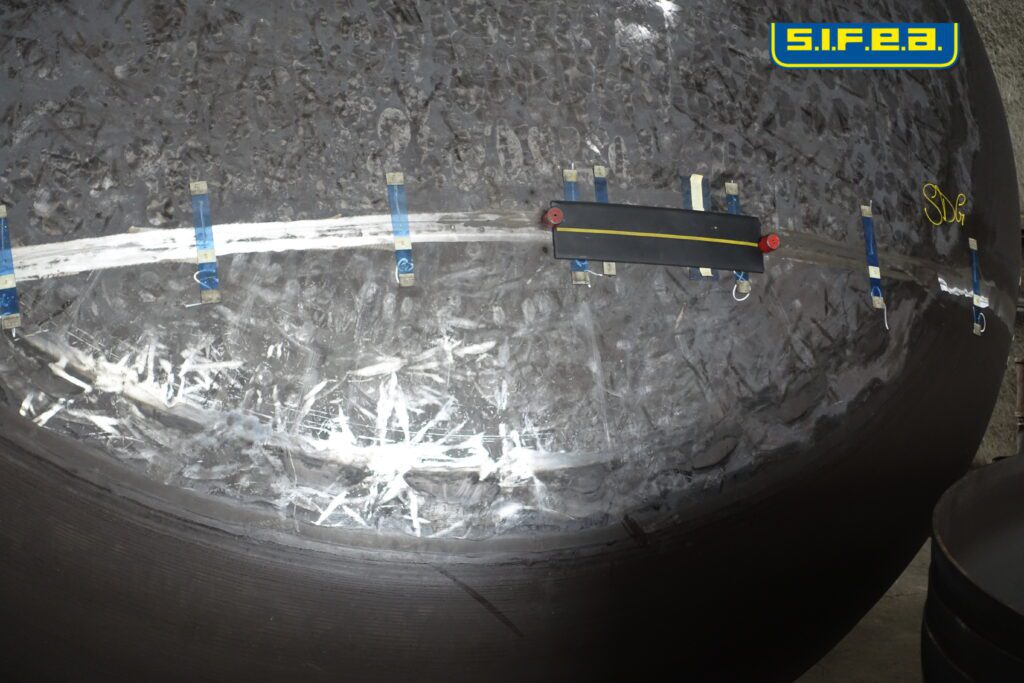

Non-destructive testing, identified with the acronym NDT, is the set of diagnostic procedures and techniques which, with the aid of increasingly advanced instrumentation and software, are used to examine materials, components and assemblies for defects and discontinuities without alter or destroy the material in question.

The most common techniques include:

• Industrial radiographs (RT)

• Ultrasound (UT)

• Magnetoscopy (MT)

• Liquid penetrants (PT)

These methods allow the detection of superficial and internal defects, ensuring that the products and manufactured products comply with the required quality and safety standards.

S.I.F.E.A. is able to guarantee, independently or in collaboration with accredited laboratories and bodies, all the checks requested by its customers.

Italiano

Italiano